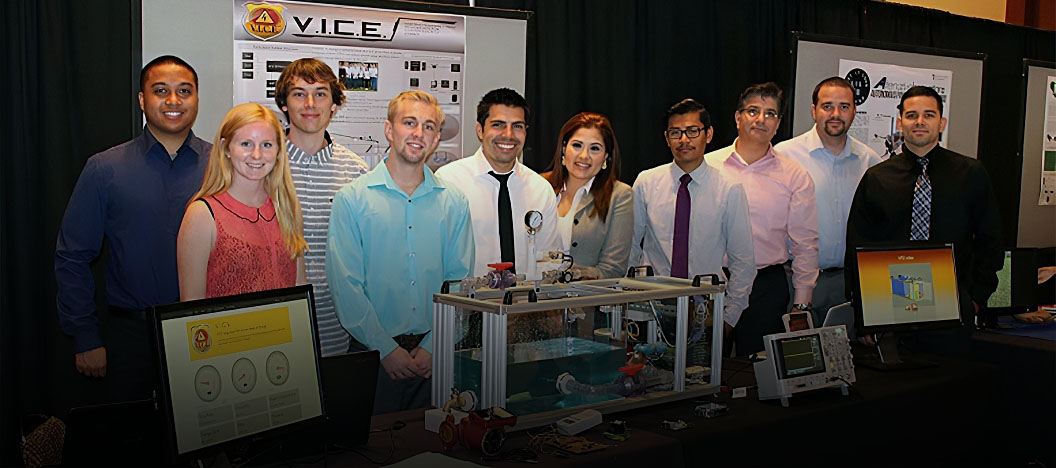

Design Day 2022

Engineering Design Day 2022 showcases innovative design projects the undergraduate Engineering students create throughout their academic year. This event is a combination of the Engineering Senior Design classes in Aerospace Engineering, Civil, Construction & Environmental Engineering, Electrical & Computer Engineering, and Mechanical Engineering.

Engineering Design Day 2022 will be held in Montezuma Hall on May 4, 2022 from 1:30pm - 4:00pm (PST).

Parking Instructions

List of Sponsors

Please visit our College of Engineering Design Day website, which has an archive of all of our Engineering Design Day events.

For previous Electrical & Computer Engineering Design Day projects, please visit:

Design Day 2021

Design Day 2020

Design Day Project

The Audio Compressor is a device that will aid the elderly or hearing impaired by helping them listen to the loud and soft passages of their audio. The user can listen to their audio through speakers or headphones. The user will have the option to choose different audio compression profiles by using a knob to cycle through each profile and pressing in the knob to select their profile. Each profile will give the user the ability to customize the dynamic range of their audio. Additionally, there will be another knob allowing the user to adjust the gain of the audio. There will be an LED to indicate to the user if their gain adjustment causes audio clipping. The current status of the system will be displayed to the user through an LCD display on the audio compressor’s enclosure.

- Team Members: Jonah Andres, Jose Belmar, Ethan Cua, Hugo Rivera Garza, Ninos Younadam

- Advisor: Professor Barry Dorr, PE - SDSU

- Sponsor: San Diego State University

- Audio Compressor for Hearing Impaired's Video

Devices used in a medical setting must have proper labeling on the exterior casing to maintain FDA certification. Team All Suds No Duds worked with sponsor Masimo to create a test device that will be capable of completing up to 100,000 cycles autonomously to test material degradation of devices. This device consists of multiple subsystems for linear motion, drainage, wiping, camera, chemical application, and electrical components.

- Team Members: Abdulaziz Alrshaid (ECE), Jason Babayev (ECE), Ahmad Bandar (ECE), Jackson Cruise (ME), Sean Eckstein (ME), Luka Emrashvili (ECE), Lauren Jansen (ME), Jared Meeks (ME), Kamar Mirza Hussein (ECE), Lori Voong (ME)

- Advisors: Dr. Chris Mi (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Mr. Chris Cardenas (Masimo), Mr. Austin Pike (Masimo), Mr. Glenn Pohly (Masimo)

- Sponsor: Masimo

- Automated Chemical Wiping System's Video

Team Licensed to Pill designed and manufactured an automated pill dispenser to ease the process and reduce the need for fine motor skills for patients and caregivers when dispensing pills into a pill organizer. The pill dispenser is able to distribute a desired amount of pills to their respective days in both weekly and monthly pill organizers, can accommodate a variety of pill shapes and sizes, and has an easy to use, high contrast Graphical User Interface.

- Team Members: Courtney Baugh (ME), Julian Ditona (ECE), Kimberly Duron (ECE), Ziyad Elfar (ME), Max Greiner (ME), Isomiddin Kamilov (ECE), Jason Kassissieh (ME), Mark Le (ECE), Ryan Shimizu (ECE), Ethan Tallorin (ME)

- Advisors: Dr. Sridhar Seshagiri (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), COL Authur Yeager (QL+), Ms. Annemarie Orr (QL+)

- Sponsor: Quality of Life Plus

- Automated Pill Dispenser (Phase III) Video

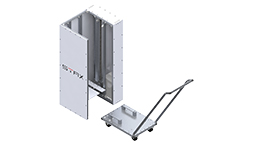

Nordson ASYMTEK dispensing systems provide automation for the semiconductor electronics market where glues and adhesives are applied to electronic assemblies. These can be at the board level, wafer level, or at a package level. This project provides an automated loading, fixturing, heating, and unloading mechanism. The objectives are to (1) provide a fixed “load” and “unload” position(s) to receive a substrate, and (2) provide a fixture to hold and heat the substrate during dispensing.

- Team Members: Abdullah Alani (ME), May Aldhaiea (ECE), Abdallah Alhajeri (ECE), Chad Bicoy (ME), Denver Chan (ECE), Zachary Chow (ME), Eric Galvan (ME), Aziz Hanna (ECE), Jose Hernandez (ME), Shervin Shabanpour (ECE)

- Advisors: Dr. Scott Shaffar (ME), Mr. David Padgett (Nordson ASYMTEK)

- Sponsor: Nordson ASYMTEK

- Automated Tooling Design for PCB Dispense Application's Video

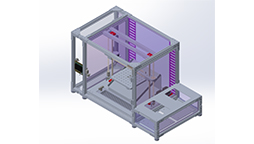

The Stax Engineering team, along with the sponsorship of Masimo, has developed the Automated Tray Tacker & De-stacker with the intent to improve the efficiency of Masimo’s production line. The machine’s design is similar to a 3D printer, where it utilizes rotational motion and converts it into linear motion through the use of a stepper motor, microcontroller, and Lead Screw. As a joint ME/ECE team, we were able to develop an automated mechatronic system that includes sensors, emergency protocols, and a touchscreen.

- Team Members: Ali Al-Azmi (ECE), Faakhir Ali (ME), Saud Al-Mutairi (ECE), Ian Estacio (ME), Steven Magayanes (ME), Karim Omara (ECE), Alejandro Ortiz (ECE), Joel Osuna (ME), Chaitanya Patel (ECE), Kevin Uy (ME)

- Advisors: Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Mr. Pratul Singh (Masimo)

- Sponsor: Masimo

- Automated Tray Stacker & De-stacker (Stax TSD) Video

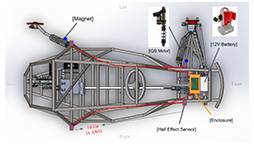

Aztec Baja Active Suspension System Team delivers an electrically controlled suspension system that dynamically responds to variable terrains for the SDSU Baja SAE club competition race vehicle. Upgrading the mechanical suspensions of the 2019 car, our controller replaces the same functionalities of the FOX intelligent Quick Switch (iQS) commercial-off-the-shelf soft, medium, and hard shock settings and adds a custom “Active” mode in response to wheel position and speed.

- Team Members: Da Chung, Kyle Hill, Benjamin Johnson, Desmond Maxwell, Eric Rosas

- Advisor: Professor Barry Dorr, PE - SDSU

- Baja Active Suspension System's Video

The objective of this project is to design and fabricate a device that increases the hardness and surface finish of a wooden, professional league baseball bat by rubbing along the barrel with a harder material. The design employs a pneumatic cylinder to apply pressure to the bat barrel and two stepper motors to rotate the bat and move the pneumatic cylinder along the bat barrel. This system has been designed to operate at adjustable bat diameters and lengths offered by Vander Pro Sports.

The Sluggineers and their project were featured on the local San Diego KGTV 10News. To see the news feature, click on SDSU Engineering Students Create a System to Make Baseball Bats Denser

- Team Members: Abdulwahab Altawheed (ECE), Vincent Chang (ME), Audrey Paris Chuakay (ECE), Anthony Gugg (ME), Scot Haury (ME), Steven Matti (ECE), Devin Morningstar (ME), Loran Najjar (ECE), Pat Petel (ME), Brandon Pola (ECE)

- Advisors: Dr. Scott Shaffar (ME), Professor Ken Arnold (ECE), Professor Barry Dorr (ECE), Mr. Victor Escobedo (D&K), Mr. Luciano Silva (Vander Pro Sports), Mr. Miguel Valle (Vander Pro Sports)

Sponsor: Vander Pro Sports - Baseball Bat Finishing System's Video

HappyTunes is a portable speaker, using a discrete class D audio amplifier developed by the team. The system is powered by a classic car’s 12 volt auxiliary power port, placed in a convenient location of the vehicle, used to improve the overall sound experience, and be easily removed to maintain the original aesthetics of the vehicle. Furthermore, the device may also be powered via an electrical outlet.

- Team Members: Brian Ahlers, Abraham Carranza, Kaitlyn Hamiter, Christopher Johnson, Christopher Kihano

- Advisor: Professor Barry Dorr, PE - SDSU

- Sponsor: San Diego State University

- Class D Audio Amplifier's Video

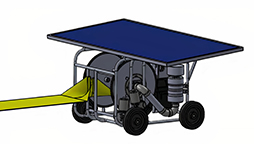

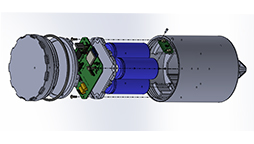

Transnational Criminal Organizations (TCOs) are using autonomous surface vessels to transport contraband undetected across the Maritime Boundary Line. Such vessels are difficult to detect, so they pose a threat to national security. Therefore, the United States Coast Guard requires a fully autonomous vessel under a materials budget of $700 that is similar to previously seized vessels and is as advanced as possible in order to determine the best method to detect them before they reach their destination.

- Team Members: Ahren Kimo Aguinaldo (ECE), Frank Aosman (ECE), Abdulaziz Bandar (ECE), Shane Cooke (ME), Jason Lin (ECE), Jorge Martinez (ME), Kyle McCoy (ME), Ivan Orozco (ECE), Andrew Preece (ME), Juan Rojas (ME)

- Advisors: Dr. Baris Aksanli (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE); LCDR Eric C. Watkins, Jr. (USCG)

- Sponsor: Ocean Aero, U.S. Department of Defense NSIN, U.S. Department of Homeland Security United States Coast Guard

- Detect Unmanned Automated Vessel's Video

Our system is a smart upgrade for conventional doorbell systems that works with the existing residential doorbell components and provides an easy upgrade. It interfaces with an existing 16-24V doorbell and its wiring. When a visitor presses the button, an optocoupler passes a 5V digital signal to an Arduino with Wi-Fi capabilities. When the button is pressed, it sends an event to a host server that uses IFTTT protocol to generate an email and send it to a phone app.

- Team Members: Rashed Abdullah, Rawan Althrwi, Zewei Liu, Jose Perez, Eddie Salazar

- Advisor: Professor Barry Dorr, PE - SDSU

- Doorbell Alerting System's Video

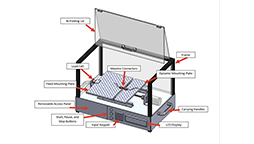

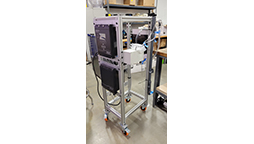

Connector Resistance and Force Tester (C.R.A.F.T.) is an electrically integrated linear mating cycle test system capable of measuring insertion/removal forces and electrical resistance of connectors of various shapes and sizes. This system was designed for Masimo, a medical device company focused mainly on noninvasive patient monitoring, with the purpose of testing their multiple connectors’ lifespan and their mechanical and electrical properties. C.R.A.F.T. is a benchtop sized, fully enclosed system, designed with both mechanical and electrical components. With a user-friendly interface, C.R.A.F.T allows the operator to determine customized parameters for each connector during setup such as cycle speed, travel distance, and connection time.

- Team Members: Fahad Alsahli (ECE), Mark Blair (ECE), Jeffrey Calimbahin (ECE), Thomas Floisand (ME), Andrew Jefferson (ECE), Nereyda Lopez Resendiz (ME), Christine Maryfield (ME), Belinda Nguyen (ECE), Jake Prittie (ME), Han Tang (ME)

- Advisors: Dr. Scott Shaffar (ME), Dr. Hakan Töreyin (ECE), Professor Barry Dorr (ECE), Mr. Chris Cardenas (Masimo), Mr. Austin Pike (Masimo), Mr. Glenn Pohly (Masimo)

- Sponsor: Masimo

- Electric Integrated Linear Mating Cycle Test System's Video

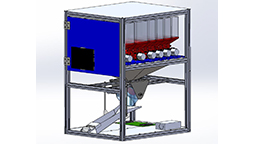

This project involved the design, fabrication and tesing of a consumer, self-serve granola dispensing kiosk. The design solution takes into consideration the customer’s ingredient choices as well as the desired serving size. It then uses its control system to maneuver all the mechanical components responsible for measuring, mixing, and dispensing the granola. The secondary goal of this project is to provide a modular design that may be utilized in future kiosks that D&K may be looking to manufacture.

- Team Members: Kimo Barrere (ECE), Paris Bee (ME), Claudia Callejas Dominguez (ECE), Adhel AJ Corpuz (ME), Conrado Dela Rosa (ECE), Joe Huang (ECE), Daniel Izarraras (ME), Xavier Lovato (ME), Zayne Mirza (ME), Evaristo Rodriguez (ECE)

- Advisors: Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Mr. Dusty Fisk (D&K Engr), Mr. Wayne Jackson (D&K Engr), Mr. John Reep (D&K Engr)

- Sponsor: D&K Engineering

- Granola Kiosk's Video

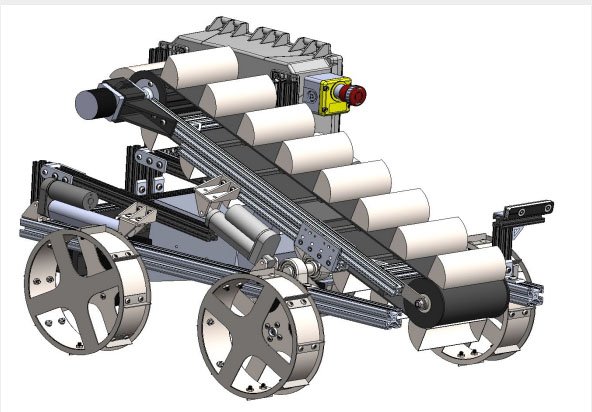

Team HADES is representing San Diego State University at the NASA Robotic Mining Competition (RMC) Lunabotics 2022 by designing, building, and operating a lunar mining robot. The goal of NASA RMC is to find innovative solutions to extract material from beneath the lunar surface using a partially autonomous robot with a dust-free operation/design. The competition is an engineering challenge in which students gain experience with the engineering lifecycle process, from concept development to system closeout.

- Team Members: Sterling Belaire (ME), William (Billy) Bilicki (ME), Alyssa Brunen (ME), Andrew Chung (ECE), Linda Clark (ME), Nathan de Chambeau (ME), Josh Dolled (ECE), Jaquelyn Fernandez-Iniguez (ECE), John Paul Edwin Ventura (ECE), Jean Michel Vives (ECE)

- Advisors: Dr. Zahra Nili Ahmadabadi (ME), Dr. Sridhar Seshagiri (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE)

- Sponsor: NASA, San Diego State University

- Handy Aztec Dig Extraction System's Video

Most current powered prosthetics serve the purpose of assisting the user with their everyday walking. Our team was challenged to design a more advanced prosthetic capable of going on long hiking and hunting expeditions in inclement weather. Our prosthetic uses a linear actuator in series with a spring to provide powered assistance to the user’s gait, making it easier and more comfortable for them to hike and walk on uneven terrain.

- Team Members: Nasser Almarshoud (ECE), Susana Arellano (ME), Dina Batros (ECE), Matthew Blake (ME), Zach Brueggeman (ME), Marc Anthony Do (ME), Garrett Grommes (ME), Justin Killam (ECE), Jarel-John Macanas (ECE), Sony Shosani (ECE)

- Advisors: Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Ms. Annemarie Orr (QL+)

- Sponsor: Quality of Life Plus

- Hiking Powered Prosthetic's Video

Current robotic pool cleaners exist as either hard-wired to an external power source or battery operated with manual periodic charging, similar to current robotic home vacuums. The project researched inductive charging methods, pool cleaning technologies and various regulatory and practicality concerns. The team designed and fabricated a working prototype of an inductive charging system for Fluidra’s robotic pool cleaner.

- Team Members: Abdulmohsen Alabdulkarim (ECE), Aeron Joshua Gonzalves (ECE), Mohammed Mohammed (ECE), Uriel Molano (ECE), Paul Nguyen (ME), Truong Nguyen (ME), Rene Orellana (ECE), Alejandro Ortuno (ME), K'Von Tanner (ME), Shane Wegener (ME)

- Advisors: Dr. Chris Mi (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Mr. Dustin Borg (Fluidra), Mr. Brian Liss (Fluidra)

- Sponsor: Fluidra North America

- Inductive Charging Pool Cleaning Robots's Video

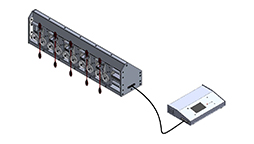

The Electrically Integrated Cable Bend Cycle Test System is designed to test the durability of medical-grade cables manufactured by Masimo. Our device features five independently controlled motorized workstations to carry out flexion stress tests and comes equipped with fully automated testing procedures. Key technologies built into the device include: precision motor control, adjustable workstations coupled with an ergonomic cable mounting system and continuity detection.

- Team Members: Abdulwahab Alqurtas (ECE), Kyle Collins (ME), Grace Fraser (ME), Brandon Lipscomb (ME), Joseph Marquez (ECE), Christopher Martin (ME), Jeremy Minimo (ECE), Alfonso Monroy (ECE), Phummin Rotphan (ME), Frank Slewa (ECE)

- Advisors: Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Mr. Desmond Mok (Masimo), Mr. Glenn Pohly (Masimo), Mr. Jonathan Truesdell (Masimo)

- Sponsor: Masimo

- Integrated Cable Bend Cycle Test System's Video

To test the quality of filters, Fluidra performs tests in accordance with the NSF 50 standard for pool equipment. For this, the team was tasked with designing a system capable of measuring the particle size/count in the water at the inlet and outlet of a filter, be able to draw water from two tanks, measure and throttle the flow rate in the system, measure the pressure across a filter, read the temperature of the water, and measure the turbidity (measured in NTUs) at the inlet and outlet of the filter, all in real-time.

- Team Members: Ameer Alhelli (ECE), Ahmad Ali (ECE), Nicholas Davis (ME), Jose Maldonado Villarreal (ME), Zachary McGraw (ME), Kevin Nguyen (ECE), Laith Noeil (ECE), Christopher Torres (ME), Brian Tran (ME), Kenny Truong (ECE)

- Advisors: Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Ms. Merinda Nugent (Fluidra)

- Sponsor: Fluidra North America

- Particle Measure Pool Filtration Test System's Video

In support of SDSU materials search, team Sintering Engineers have created a sintering chamber that includes a Proportional–Integral–Derivative (PID) controller system for an existing Microwave Press. The PID controller will utilize input data from the materials’ increase in temperature and difference in the emitted and reflected power over time, to govern the energy emitted from the magnetron. The intention is to flash sinter a powder based material, under pressure to create more homogeneously transparent material and progress microwave sintering technology.

- Team Members: Omar Alshatti (ECE), Logan Beltz (ECE), Gabriel Facco Bettinelli (ECE), Dante Gonzalez Corbett (ECE), Aquin Manners (ME), Christopher Sarabia (ME), Eric Segura (ME), Jimmy Tran (ECE)

- Advisors: Dr. Scottt Shaffar (ME), Dr. Elisa Torresani (ME)

- Sponsor: SDSU, Powder Technology Laboratory

- PID Controlled Microwave Press's Video

The Roving Alarm Notification System (RANS) is a security system designed to give nearby roaming personnel up to date location information for designated security zones. This iteration of the system seeks to upgrade the obsolete components and the memory storage of the device.

- Team Members: William Bowling, Raul Palomo, Zachary Tarkowski, Isaiah Webster, Kevin Wuertz

- Advisor: Professor Barry Dorr, PE - SDSU

- Sponsor: Mr. Dennis Berglund, PE, Priax Corporation

- RANS Product Update's Video

The Rapid Deployment Runway Closure System is an inflatable system developed to quickly deploy and retract to prevent the landing of unauthorized aircraft on remote airstrips by exhibiting the appearance of a barrier. The inflatable is anchored by a ground stake and an off-the-airstrip housing complex containing the blower, power supply, and control system. The system was engineered to be operable by a single person and adhere to airstrip safety protocols.

- Team Members: Sean Connolly (ECE), Alyssa Elkins (ME), Khalid Nunow (ECE), Jomari Paguia (ECE), Marc Tanwangco (ECE), Timothy Turner (ME), Nick Wolford (ME), Bianca Yousif (ECE), Ala Zeidan (ME)

- Advisors: Dr. Chris Mi (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE), Mr. Phillip Benham (BAS)

Sponsor: Benham Aviation Services - Rapid Deployment Runway Closure System's Video

California coastlines have awe inspiring world class beauty, however cliff bluffs with hidden dangers put public safety at risk. Our solution is to deploy a long range underground wireless sensor probe network capable of localized real-time event data processing of: seismic data, tilt changes, temperature and soil conductivity. Our system is both wireless rechargeable, and has redundant wireless data download pathways to maximize operational longevity.

- Team Members: Po-Hsien Chen (ME), Eliott Giberson (ME), Nicolas Kano (ME), Kassandra Marquez (ECE), Adrian Melgoza (ME), George Mirza (ME), Tristan Schultz (ECE), Richard Stoddart (ECE), Harrison Ward (ECE), Kevin Winchell (ECE)

- Advisors: Dr. Christopher Paolini (ECE), Dr. Scott Shaffar (ME), Professor Barry Dorr (ECE)

- Sponsor: SDSU Electrical & Computer Engineering

- Seismic System for Detecting Beach Bluff Collapse's Video

The goal of this project is to create a system which allows a drone upon landing to autonomously dock with, and be secured to a ground based landing pad. The drone will include a control system and sensor suite that is able to detect the landing location, maneuver itself toward, and align itself with the landing pad. The landing pad will then mechanically secure the drone once the landing procedure is complete. When the drone is ready to leave the landing pad, the process will happen in reverse and allow autonomous flight to once again occur.

- Team Members: Christopher Bowman (ECE), Charles Kaui (ECE), Nicholas King (ME), Bryce Kirklen (ME), Cesar Nuno-Banuelos (ECE), Angelo Peck (ECE), Chanthol Phea (ECE), Robert Spiers (ME), Nathaniel Thomas (ME), Fady Yousif (ECE)

- Advisors: Dr. Scott Shaffar (ME), Dr. Junfei Xie (ECE), Professor Barry Dorr (ECE), Mr. James Down (Northrop Grumman), Mr. Andrew Simmons (Northrop Grumman)

- Sponsor: Northrop Grumman

- Self-Securing Landing Mech for VTOL Autonomous Vehicle's Video

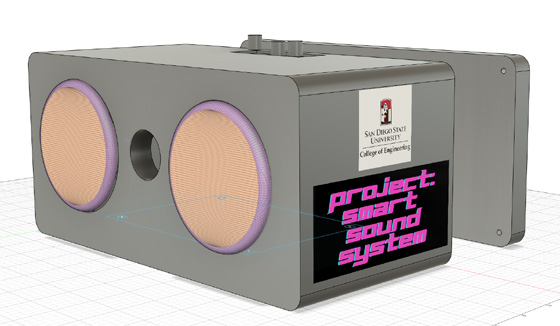

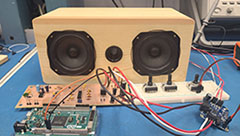

The Smart Sound System 555 (SSS-555) is a stereo audio system that will periodically detect ambient noise levels to automatically adjust the sound levels produced internally not to exceed a set threshold for volume and only 10-15 dB above the ambient noise level.The SSS-555 sound system is being developed to deliver stereo quality audio without the need for excess space and or complexity.

- Team Members: Mubarak Aljadei, Maximillan Guinto, Alexis Llamas Zamora, Nazreth Negash, Lana Pantskalashvili

- Advisor: Professor Barry Dorr, PE - SDSU

- Sponsor: San Diego State University

- Smart Sound System's Video

Enersion is a clean energy start-up with a system called tri-generation where they provide cooling, heating, and electricity to a customer. To assist their analysis, we created a GUI that displays input data such as solar availability, electrical and hot water usage, cooling load, and compares it with the projected energy capabilities of various sizes of Enersion’s system. Ultimately, a cost of energy upkeep and carbon footprint analysis is output to help a customer realize the benefits of installing Enersion’s system.

- Team Members: Dennis Chhoeuk, Zackary Hollingworth, Eduardo Mercado Figueroa, Elise Serrano, Steven Shaaya

- Advisor: Dr. Saeed Manshadi - SDSU

- Sponsor: Enersion

- Solar Tri-Generation's Video

The THT-21, for Tobacco, Humidity and Temperature 2021, is being developed to serve as a more accurate and dependable technology for monitoring conditions of drying and fermenting warehouses used on a tobacco farm in Nicaragua. There is a need for this technology as the current tools being employed are obsolete, and the farm experiences heavy product losses when conditions fall out of ideal ranges (26-30°C and 80-90% relative humidity).

- Team Members: Andrew Castillo, Collin Chapman, Maria Del Pilar, Cheryl Hagar, Mata Gomez

- Advisor: Dr. Ying-Khai Teh

- Sponsor: Mr. Alejandro Mata Alfambra - Alfambra Cigars

- THT-21's Video

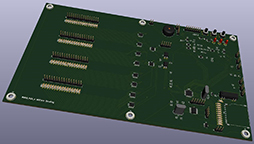

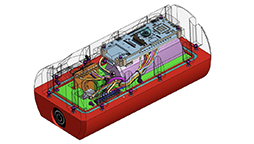

Marines require a sophisticated understanding of where adversary forces are located within their battlespace. The USMC small ground sensor project can provide the Marine ground forces with a deployable compact sensor system that includes audio, visual, seismic, and GPS data to fully understand an evolving battlespace. The Phase 2 teams focus is on optimizing the form factor, reliability, durability, weight, and performance.

- Team Members: Mohammed Alfailakawi (ECE), Dwight Anthony Diesmo (ECE), Jhovanna Garcia (ME), Nathan Mincks (ME), John Pawlak (ME), Marcos Rodriguez (ME), Kaylin Sabado (ME), John Sadiq (ME), Nina Truong (ECE), Riley Turner (ECE)

- Advisors: Dr. Duy Nguyen (ECE), Dr. Scott Shaffar (ME), Mr. Kevin Demesa (USN), Ms. Cassie Heyman-Schrum (NSIN)

- Sponsor: NSIN, USN, USMC

- USMC Small Ground Sensor's Video